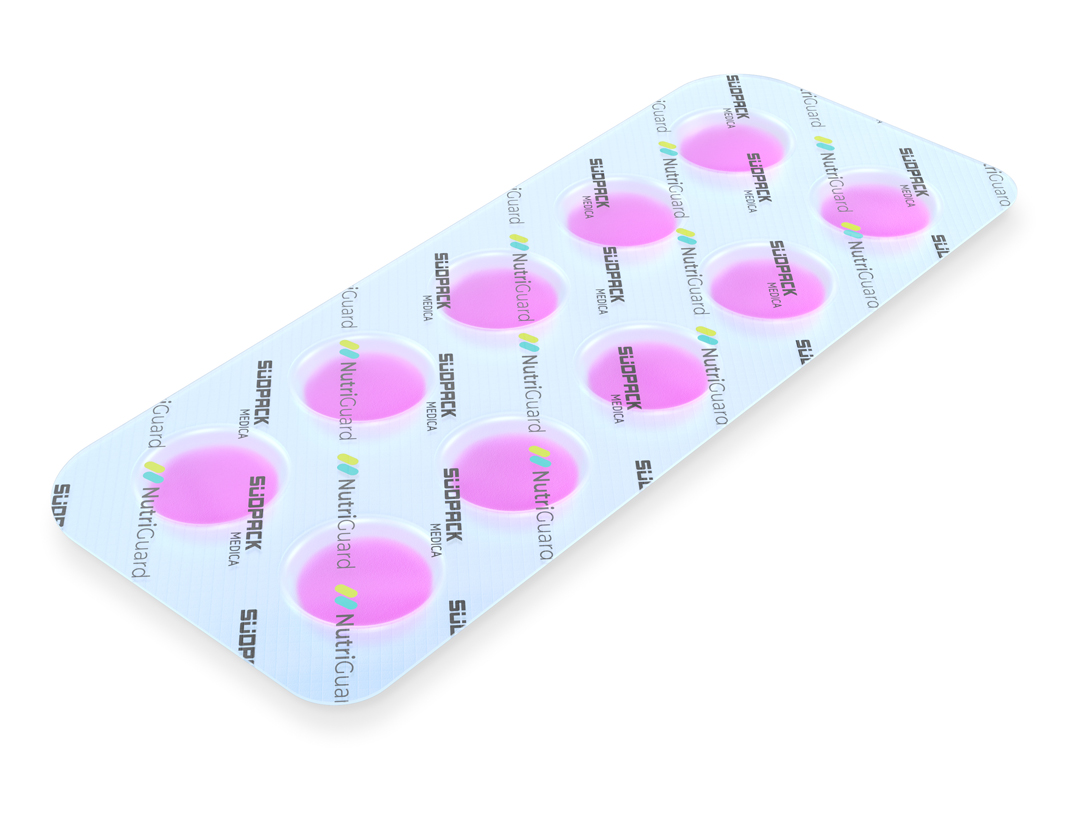

NutriGuard®

blister packaging

NutriGuard stands for innovative, recyclable blister packaging based on polypropylene, developed specifically for nutraceuticals. This future-ready packaging solution is perfectly aligned with tightening regulatory requirements and rising consumer expectations. As sustainability takes on greater importance, nutraceuticals need packaging that strikes a balance between performance and environmental responsibility.

Starting in 2025, companies will gradually face fees under the Extended Producer Responsibility (EPR) regulations. In certain countries, products with greater recyclability and lighter packaging will be subject to lower fees. From 2030 onward, the statutory recyclability requirements will become even more stringent. Consequently, packaging for nutraceuticals will need to achieve a minimum recycling rating of “C” – as these products are not eligible for special exemptions (such as those granted to medical packaging) and are therefore subject to general recycling standards.

NutriGuard offers a future-ready solution that not only meets the regulatory requirements but also helps reduce EPR-related costs. Take advantage of our packaging solution – reduce your environmental footprint and ensure economic profitability in an increasingly sustainability-driven market.

NutriGuard is a polypropylene-based blister packaging solution with barrier properties. Classified as recyclable, it meets all current sustainability requirements. At the same time, it provides familiar push-through performance, comparable to conventional blister packaging (PVC / PVdC / aluminum). In addition, the push-through resistance can be precisely adjusted without compromising barrier integrity.

The Packaging and Packaging Waste Regulation (PPWR) sets clear requirements for the future of sustainable packaging, focusing on three main criteria:

Ban on PFAS: The use of PFAS will be heavily restricted, with strict limits coming into effect as early as August 1, 2026.

Incorporation of recycled materials: Packaging must include a specified proportion of recycled content.

Large-scale recyclability: Packaging must be designed for efficient recovery within a functional, scalable recycling infrastructure.

NutriGuard is a tailored response to these evolving challenges. Our innovative packaging solutions are aligned with a range of application-specific requirements – NutriGuard also offers various solution-oriented approaches tailored to your use case. Choosing NutriGuard means investing in a future-proof packaging solution that not only complies with the upcoming regulations but also actively supports your company’s sustainability goals.

NutriGuard is a fully mono-material solution suitable for mechanical recycling – making it a future-ready option that already meets the upcoming regulatory requirements. In addition, our in-house material management system supports the use of regranulates, enabling us to further improve the eco-balance.

Sustainability is becoming a critical factor in packaging decisions. Via screening LCAs, we compared our recyclable, PP-based NutriGuard blister packaging to other common solutions – and the results speak for themselves: Switching from PVC + aluminum to NutriGuard can reduce CO2 emissions by around 39%. Even compared to a mono-material solution made from PET + APET, NutriGuard offers a CO2 reduction of around 15%.* Therefore, adopting our packaging solution can make a measurable contribution to reducing your environmental footprint.

*Calculations based on screening LCAs.

PET/aluminum: 100% incineration

PET, PE, and PP: German recycling mix

Depending on the product to be packaged, our NutriGuard films can be equipped with different barrier properties to ensure optimal product protection. Their push-through resistance can also be precisely adjusted – without compromising barrier integrity. This versatile blister packaging is suitable for a wide range of applications, including nutraceuticals in tablet form as well as other products. A key advantage of this film is its consistently high water vapor barrier across the full residual wall thickness, providing excellent aroma protection. Since the barrier effect in polypropylene is created by the material itself and not by means of a comparatively thin coating, the measurement of the residual wall thickness provides more reliable information about the expected barrier effect. This also simplifies quality control during the packaging process.

Our recyclable NutriGuard blister solution delivers excellent processability thanks to its wide processing and thermoforming window, which allows energy-efficient, low-temperature forming and sealing.

The NutriGuard top web offers excellent printability without requiring corona or other pre-treatment. It is well suited for inline printing using HAPA and Domino printing technology during the packaging process. All inks used comply with food safety standards under EU Regulation 10/2011. Alternatively, NutriGuard can be printed by SÜDPACK Medica using the flexographic printing process.

NutriGuard is an innovative, recyclable blister packaging solution designed for nutraceuticals such as vitamins, minerals, and other VMS products. It is suitable for packaging powders (e.g., turmeric powder), capsules (e.g., vitamin D capsules), and tablets. NutriGuard is equally suitable for probiotic supplements or yeasts that require enhanced barrier properties. It offers clear advantages for dietary supplement applications by combining sustainability with dependable product protection.

Packaging for nutraceuticals must fulfil key requirements regarding product protection, user convenience, and sustainability.

Product protection: The packaging must reliably safeguard the product to preserve the quality and effectiveness of its ingredients.

User-friendliness: Consumers expect easy handling – for example, familiar push-through functionality.

Sustainability: The packaging should be eco-friendly and recyclable.

Mono-materials are particularly well suited for packaging nutraceuticals. Our polypropylene (PP) blister solution is highly recyclable and offers flexible barrier properties. At the same time, it provides familiar push-through performance, comparable to conventional blister packaging (PVC / PVdC / aluminum).

Yes! As the manufacturer of a sustainable blister solution based on polypropylene (PP), we offer fully recyclable packaging for nutraceuticals. Our PP blisters reduce the overall environmental footprint while delivering outstanding product protection and ensuring compliance with PPWR requirements.