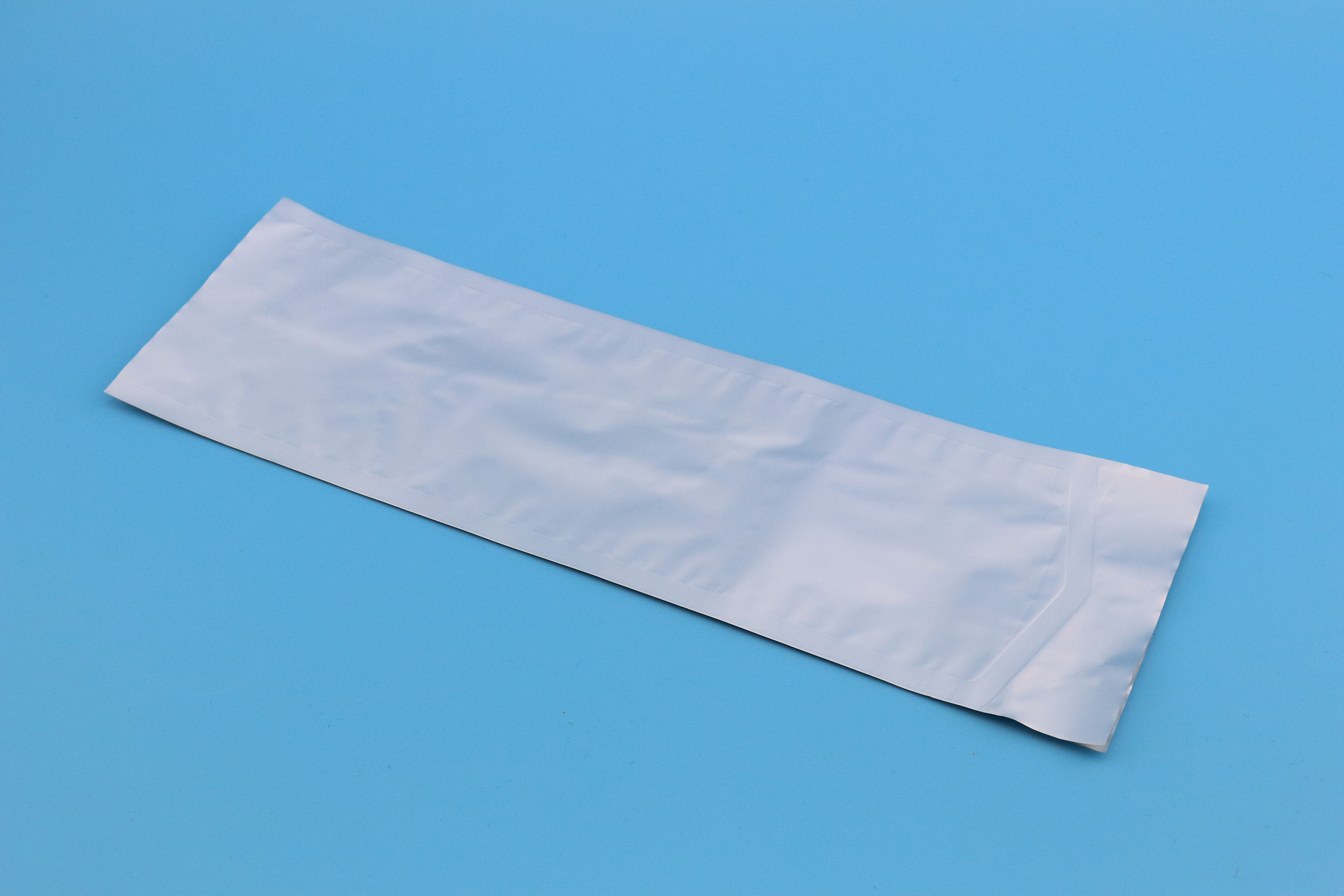

Optimal conditions with high performance barrier packaging

Active ingredient coatings on wound care products and transdermal therapy systems require protection

Modern wound management products promote the healing of chronic wounds, or play a role in the improvement of a patient’s condition in case of wound healing disorders. Today, barrier packaging is the means of choice for transdermal therapeutic systems and special wound care systems for the absorption of exudate or maintenance of a moist milieu.

SÜDPACK Medica offers different concepts for the various requirements demanded by the market. We can also supply all products printed on request.

- Pre-fabricated bag making material with integrated barrier

- Laminated films for thermoforming and flow wrap systems

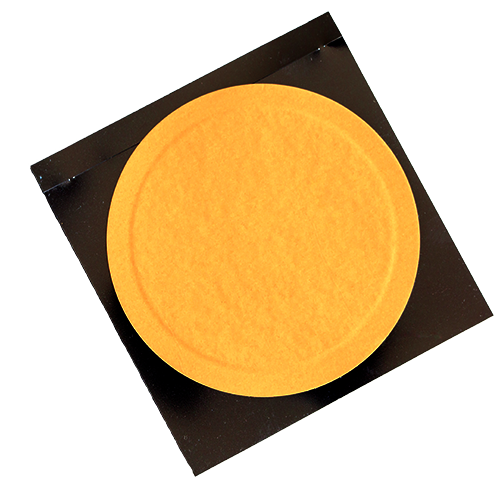

Wound management systems

Coated wound care systems are optimally protected if the packaging is able to maintain the required milieu. Only in this way can the required coating properties be maintained until application.

Our lidding films have been designed so that they can easily be separated from the bottom film without leaving residues, allowing a wide access field for removal.

With regard to the material, on the other hand, we focus on minimal curling.

For wound dressings and wound closure systems, packaging is required which offers a sufficient barrier against oxygen, light and water vapor.

Our high-quality solutions are also characterized by a gentle, non-curling peel – an important feature of such packaging systems, as only in this way can a product be accessed easily and aseptically.

Over the past years, a multitude of transdermal therapeutic systems in the form of patches with active ingredient coatings have been developed as a method of application via the skin.

Yet active ingredients and adhesive parts of such products require optimized protection during storage. For our packaging materials, we therefore focus particularly on inert characteristics so that no active ingredients react to the film or migrate into the film.