Puncture resistant primary and secondary packaging

SÜDPACK films are optimized for sealing against medical papers, robust and flexible.

Smaller operations and interventions are an integral part of everyday modern medicine.

To permit fast and safe access to needles, port systems, catheters and syringes, a sterile barrier with good peeling and opening characteristics is required. Whether standard solutions for mass items or individual systems – thanks to our expertise as a leading extrusion company, we at SÜDPACK are not only able to offer our customers a packaging concept, but also added value in all senses of the word – above all with a view to the total costs (TCO.)

- Resource-optimized

- Efficient and economically-viable

- Easy handling

Application knowledge is at our core. We at SÜDPACK understand the requirements of the market.

These products are a standard item in medical care. And yet prefilled syringes demand complex packaging requirements. One ideal solution is our thermoformable rigid films. Here the cavities can be optimally adapted to the product, so that it is securely fixed within the packaging. And for steam sterilization, we offer various different lidding films.

- Dimensionally stable and sterilizable

- High transparency

- Integrable light protection and gas barrier

These syringes are produced in high quantities and are used daily for injections and punctures. With regard to the packaging, one thing counts above all else: economic viability. We have therefore developed solutions which can be processed efficiently on all conventional machines, and which are compatible with most medical papers.

- High cycle rates due to short sealing times

- High puncture resistance

- Economical use of materials

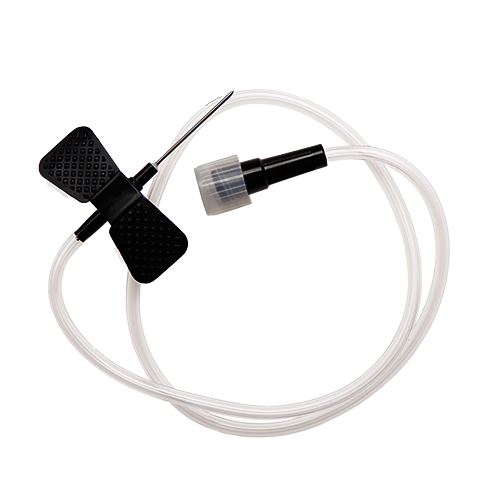

Sterility is of vital importance for small lumen tubing systems which are connected to catheters via connectors. For their packaging, peel characteristics and puncture resistance are some of the core aspects to be addressed. We therefore combine our puncture resistant flexible films with conventional medical papers for an optimized packaging result.

- Residue-free, even peel characteristics

- Puncture resistance

- All-round protection

These are mounted onto syringes and used to administer liquid drug products. The packaging required for these products is small in format, and above all highly efficiently produced. Our different flexible and lidding films not only perfectly fulfill these requirements, but can also be used on all conventional automatic molding, filling and sealing systems.

- Material-saving

- Puncture resistant

- Even peel, even with small tear areas

Do you require an effective packaging solution for injection-molded small components such as sealing plugs or connectors? The SÜDPACK portfolio includes tailored solutions. Our thermoformable rigid films can be sealed perfectly using medical papers, and, thanks to their good mold-release characteristics, offer optimized all-round protection for your products even in case of small cavities.

- Flexible

- Material-compatible

- Peelable